The Challenge Behind Alpine’s First Hydrogen V6 Intake System

The Alpine engineering team turned to CRP Technology to overcome reliability issues in the intake plenum system of the Alpenglow Hy6 hydrogen engine.

From Bonded Flanges to Monolithic Strength: The Engineering Approach

The previous version featured aluminum flanges bonded to 3D-printed parts, which caused leakage problems during dyno testing due to thermal expansion differences and vibration.

To eliminate weak points and ensure structural consistency, Alpine relied on CRP Technology for a rapid, functional redesign.

CRP Technology’s R&D and production teams proposed to re-engineer and 3D print the entire system monolithically, using Selective Laser Sintering (SLS) and carbon fiber–reinforced Windform SP, offering high stiffness, strength, and thermal resistance.

Only minor design modifications were required.

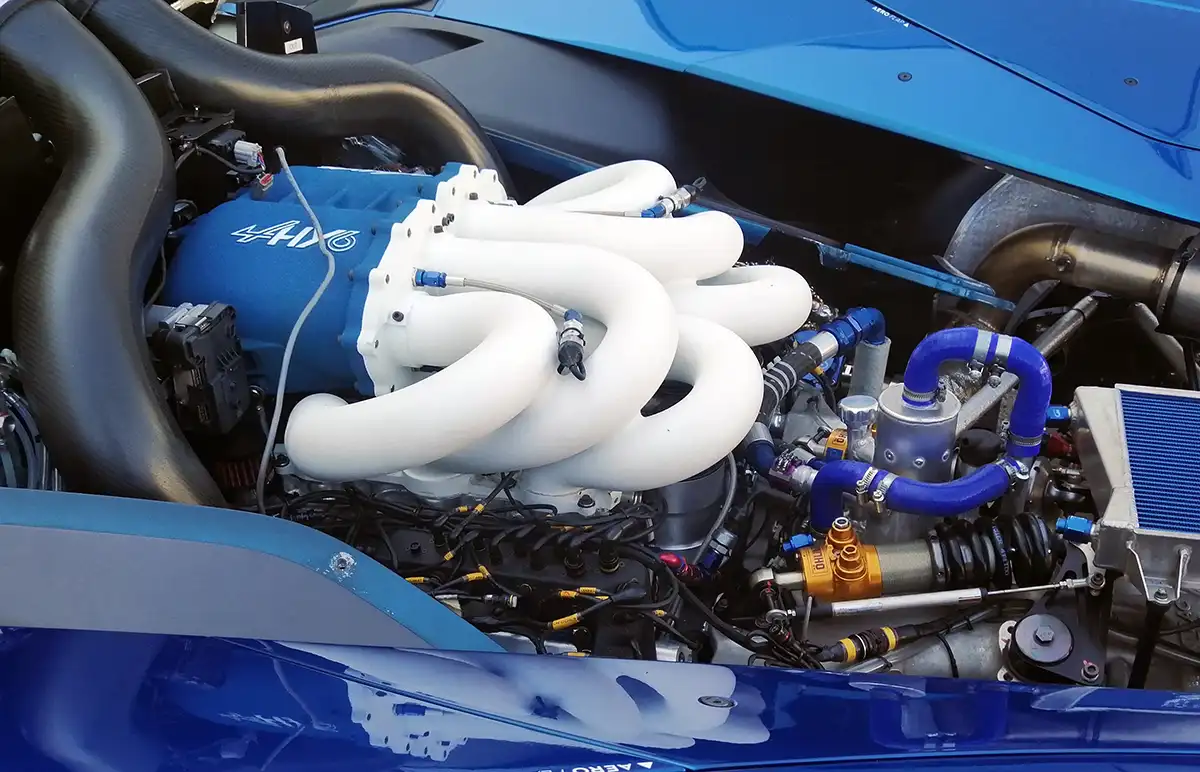

The new intake system was composed of three monolithic parts:

- One intake plenum

- Two intake manifolds (“spaghetti” inlets)

All flanges were directly integrated into the Windform SP structure, completely removing the aluminum components.

Result

The 3D-printed system proved structurally sound and functionally reliable under demanding test conditions. It successfully passed dyno validation and was installed on the Alpenglow Hy6 car for track testing.

Key achievements

No leakage or interface failure under thermal loads

5-bar pressure resistance in turbo operation

Assembly reduced to 3 monolithic components

Reduced mass and compact design with improved airflow

Faster development enabled by tooling-free process

Higher reliability from uniform material response

Post-processing included vapor smoothing for surface finish and 5-axis CNC machining, by CRP Meccanica, in coupling areas to ensure perfect assembly fit.

What This Solution Means for High-Performance Hydrogen Powertrains

By leveraging CRP Technology’s expertise in composite materials and SLS 3D printing, Alpine overcame critical thermal and sealing issues in record time.

The collaboration resulted in a lightweight, high-performance intake system capable of withstanding the extreme conditions of a hydrogen combustion engine – confirming CRP Technology as a trusted partner for real, rapid, and reliable solutions in motorsport innovation.

Alpenglow Hy6 is the hydrogen-powered hypercar concept unveiled by the Renault Group’s performance brand. Alpenglow Hy6 represents Alpine’s vision of sustainable, emotional performance.

Key Specifications

of the Alpine Alpenglow Hy6

3.5 L

Hydrogen V6 engine

740 bhp / 544 kW

@ 7 600 rpm

Power output

211 bhp/l

Specific power

9000 rpm

Maximum revs

3 × 2.1 kg @ 700 bar

Hydrogen tanks / pressure

> 330 km/h

Top speed