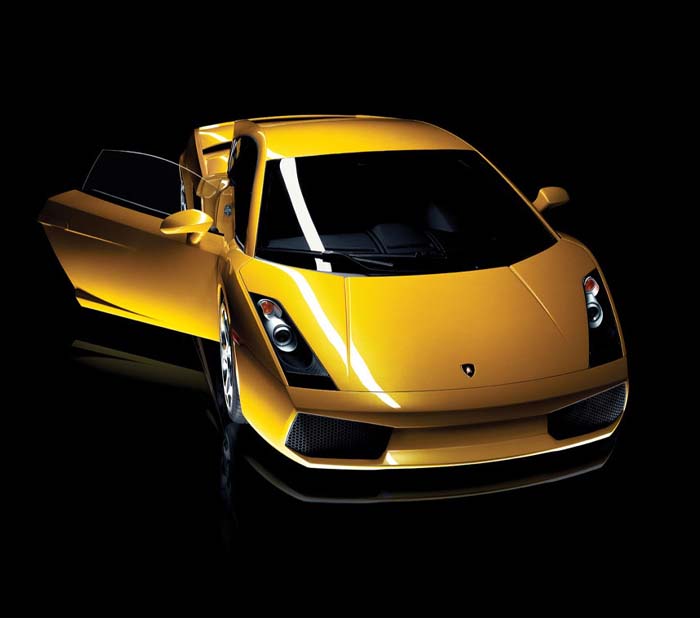

Built on 50+ years of motorsport DNA. Trusted by Aerospace, Defense & UAV primes.

Selective laser sintered in Windform® for durable, lightweight, high-performance parts.

High-Performance Alloys & metals, strict tolerances, advanced finishing.

DMLS & CNC Machining finishing for strong, accurate parts.

High-performance light alloys. Full-process finishing for complex parts.

We support companies in optimizing their design processes for Additive Manufacturing, including topological optimization through Circle Hub, to create extremely lightweight yet robust components, provided that a thorough engineering study of the component’s operational context is carried out.

Additive Manufacturing is a technology that requires distinct engineering paradigms compared to traditional methodologies.

Our expertise enables the effective integration of the constraints and opportunities of Additive Manufacturing into every stage of design, accelerating the development of functional, conceptual, or final prototypes – often without the need for dedicated tooling.

This approach significantly reduces the time between the conceptual validation of an idea and its evolution into a functional prototype, facilitating iterative refinement of the project.

A concrete example is topological optimization.

We collaborate closely with technical teams to transfer know-how and guide the transition toward the integration of Additive Manufacturing as part of an engineering-driven process, where design is guided by functionality, efficiency, and scalability.

The goal is to equip designers with the tools and solutions needed to unlock the full potential of Additive Manufacturing, enabling them to validate their ideas through tangible, immediate prototypes.

CRP holds multiple certifications across its global manufacturing network, including EN9100 for the Aviation, Space and Defense sector ensuring every part meets the highest standards of precision and compliance.

CRP Technology

Via Cesare della Chiesa, 150/C

41126 Modena - Italy

www.crptechnology.com

CRP Meccanica

Via Cesare della Chiesa, 21

41126 Modena - Italy

www.crpmeccanica.com

CRP USA

(North America)

127 Goodwin Circle

Mooresville, NC 28115 - USA

www.crp-usa.net

CRP GULF

(UAE and GCC)

Warehouse No12, Dubai Commercity

17th ST Umm Ramool Dubai - UAE

www.crp-gulf.com

Local roots, global reach. Near-customer hubs cut lead-times and emissions.

Click a point to view on-site capabilities and connect with the closest team.

CRP USA (North America)

crp-usa.net

ITAR registered Entity

CRP Technology (Modena Italy)

crptechnology.com

CRP Meccanica (Modena Italy)

crpmeccanica.com

CRP Gulf (UAE & GCC)

crp-gulf.com

Tight deadlines. Demanding specs. Production-ready results.

The industrial world is evolving fast – and every challenge calls for a different mix of expertise, technology, and market insight. At CRP, we tailor our approach to match your specific needs, combining deep sector knowledge with agile execution.

Whether you’re exploring new possibilities or looking for proven results, our case studies show how we turn complexity into clarity.

DMLS = Direct Metal Laser Sintering; EDM = Electrical Discharge Machining; PIM = Plastic Injection Moulding; SLA = Stereolithography; SLS = Selective Laser Sintering;

Discover the latest updates, innovations, and success stories from every CRP company – a consolidated window on the technologies, materials, projects, and people shaping our high-tech journey.

Don’t have to compromise between high quality and speed to market.

We deliver both – thanks to expert teams, proprietary Windform materials, cutting edge technologies, broad technical capabilities and unwavering focus on your success.